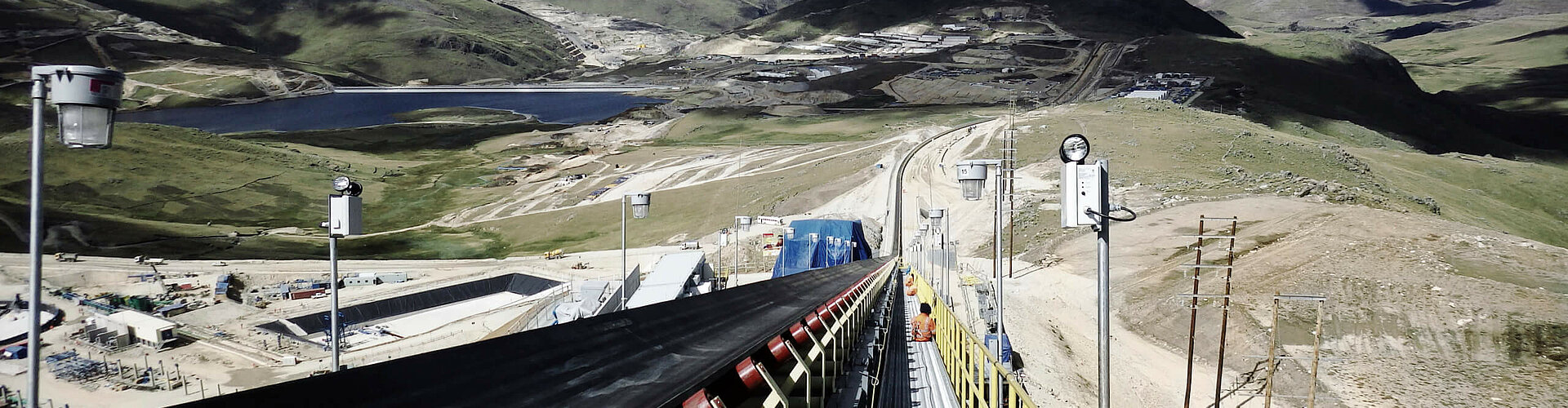

Las Bambas, Peru

TURNKEY SOLUTION FOR THYSSENKRUPP OVERLAND CONVEYORS

Semperit was entrusted by thyssenkrupp to supply and install conveyor belting for two overland conveyor systems in the Las Bambas copper mine in Peru.

thyssenkrupp Industrial Solutions has been collaborating with Semperit since 2012, trusting Semperit to support them in facing the challenges of the mining industry with innovative and reliable solutions. In recent years, due to increasingly complex requirements in mining, there has been an upturn in the use of conveyor belts with high capacities and high performance. To respond to the critical nature of these tailored solutions, thyssenkrupp and Semperit have worked closely together in order to offer the most efficient and productive conveyor systems to customers.

Over the last few years both companies have successfully implemented several projects in South America, including the Las Bambas mine. These projects are part of Semperit’ ambition to expand its footprint more widely in the region.

Project in Numbers

| Transported material | Copper |

| Horizontal installation length | 2.5 km from ore mine to processing plant |

| Conveyor length | 2.6 and 2.7 km (overland conveyors); 206 m (sacrificial conveyor) |

| Conveyor belt length | Approx. 12 km |

| Conveyor belt width | 1,830 mm |

| Conveyor belt tensile strength | 5000 N/mm |

| Transport capacity | 9,400 tph |

| Belt speed | 6.5 m/s |

| Driving power | 4.400 kW |

Las Bambas

Download fact sheet

State-of-the-art splicing technology

To make sure thyssenkrupp’s conveyor systems have the longest service life possible in order to support the Las Bambas long-term project, Semperit supplied around 12 kilometres of steel cord belts with a tensile strength up to 5000 N/mm. These high strength steel cord belts ensure reliable transport at the highest capacities and supply ultimate service life and utilisation. They are the perfect choice in the case of Las Bambas’ heavy duty mining application, where steady performance and durability are key. For this project Semperit also delivered adapted splicing kits. The splicing process was completed in July 2015 under Semperit supervision, guaranteeing top quality splices and splice longevity. After-sales customer support was another value-add service thyssenkrupp benefitted from. After the belts were installed Semperit sent an Application Engineer on-site to provide expert appraisal and advice on optimum conditions for longlasting conveying operations thanks to our belts.

Semperit Solutions

Sempercord is the best choice in case of

- Heavy duty conditions

- Highest transport capacities

- Long centre distances

- High nominal belt strength requirements

Sempercord

HEAVY STEEL CORD BELT

THE BEST CHOICE FOR SEVERE OPERATING CONDITIONS

Sempercord high strength steel cord belts are a combination of ultimate carcass breaking strength and lowest elongation.

They are made with high-tech rubber compounds and in-house produced steel cords, thus ensuring complete control over the product quality. Widely used in heavy duty mining applications, as well as industrial environments where reliable performance and availability are key, Sempercord belts comply with all major international standards as much as they can be specified for meeting individually exceeding requirements of high end users.